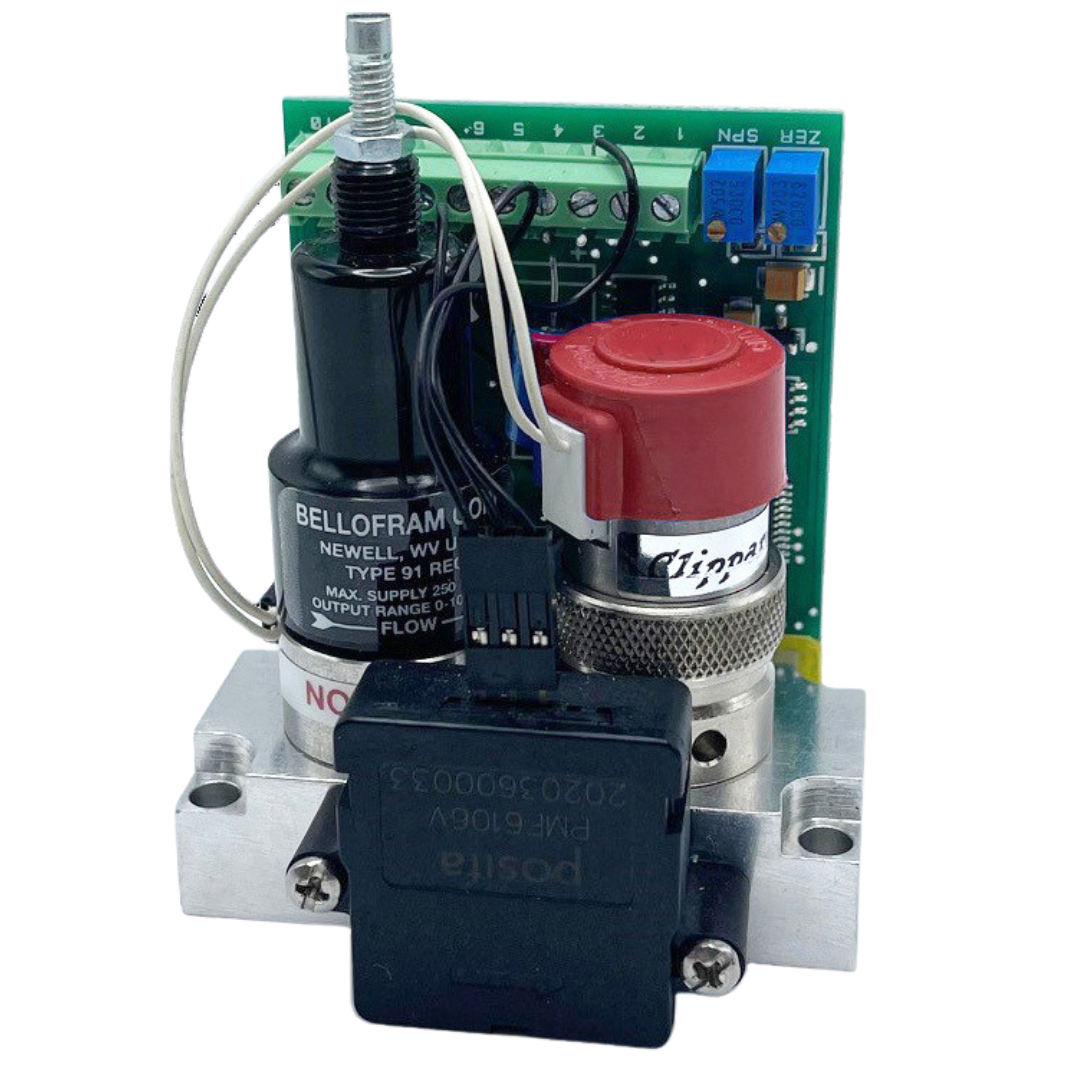

Electronic Flow and Pressure Controls - MD4000

Electronic Pressure Control and Electronic Flow Control

Crafted for peak performance in medical devices, the MD4000 Proportional Electronic Flow and Pressure Controls seamlessly integrate sensors, command signal scaling, and valves, ensuring unparalleled precision. This system offers versatile electronic pressure control and electronic flow control, effortlessly adapting to both analog and digital (MODBUS RTU) command signals. Customize your analog output to align with setpoint, remote sensor, or output values, all with the flexibility of forward or reverse action. The MD4000 accommodates space constraints with manifold or DIN tray mounting options. You can also opt for an integrated mechanical pressure regulator for improved flow control, along with the choice of a non-relieving function (no exhaust valve) for pressure control. With flow ranges reaching 700 lpm, the MD4000 Series adds versatility to cutting-edge medical solutions.

FEATURES

- Pressure and/or Flow control

- Dual valves with on board sensor for pressure control

- Single valve with on board flow sensor for flow control

- Stable PID control

- RS-485 serial communication w/ MODBUS RTU protocol

- Analog Input: 0-5VDC, 0-10VDC or 4-20mA

- Analog Output: 0-5VDC, 0-10VDC

- Auxiliary input for second loop feedback downstream

- Proportional operation

- Manifold or DIN tray mounting

- Proprietary computer software for full access to remote monitoring and setup

- Optional on board mechanical regulator for flow control

- +24VDC or +12VDC supply options

FOCUS MARKETS/APPLICATIONS

- Ventilators

- Anesthesia Systems

- Pulmonary Function Testing Equipment

- Neurodiagnostic Devices

- Oxygen Concentrators

COMPETITIVE ADVANTAGES

- 0.5% accuracy full scale (pressure)

- 2.0% accuracy full scale (flow)

- Proportional valves do not need to fully close as often, reducing wear and extending life

- Closed loop feedback provides stability and precision

- Optional mechanical regulator allows higher maximum input pressure